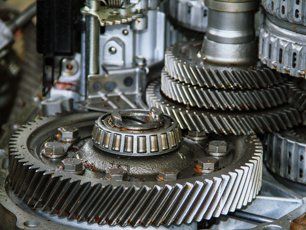

- Industrial Gearbox Repair

- Automatic Gearbox Repairs Near Me

- Driveshaft Repairs Near Me

- Automatic Gearbox Repairs Near Me

- Vw Gearbox Repairs Near Me

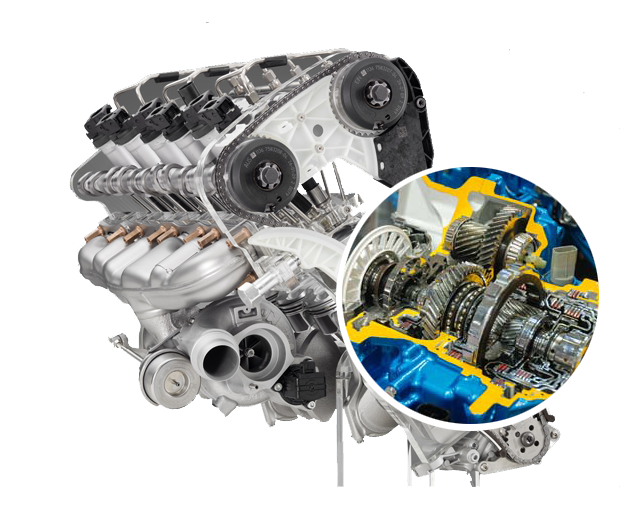

Standard Machine brand products are part of a distinguished legacy of over 40-years of design, manufacturing, and service expertise throughout Canada. Our regional service center offers customers fast turnaround times for the inspection, overhaul, upgrade, and full-speed testing of their repaired gearboxes, no matter who the original equipment manufacturer was. Standard Machine personnel, which includes expert machinists and design engineers, are thoroughly skilled in performing industrial gear box failure root cause analysis so we can offer suggestions for not only repairing gearboxes but upgrading them to prevent future failures and extend the lifecycle of your gear drive.

Gearbox repair and rebuild services to the industry nationwide, United Gear Works available 24 hours a day, 7 days a week We have been for over 55 years in repair industry. As your equipment gets old the various wear surfaces can develop ridges - grooves or flat spots from regular usage. Call us before the small problems become major. Global service network with more than 30 wholly owned gearbox service and repair centres worldwide; Our capabilities. The experts in industrial gearboxes Our extensive history has seen us work with the worlds’ biggest industrial companies. We are constantly in operation all over the world, using our expertise to solve any gearing problems.

Visit our pages on Western gearboxes and WesTech gearboxes to find out more information about our OEM gearbox design and manufacturing, repair capabilities, Onsite Technical Services, and replacement parts.

OtherBrandsWeSupport

| Representative List of Brands for Gearbox Repair | ||

| Allen Gear | Farrell | Marley |

| Amarillo | Flender | Mitsubishi |

| BHS-Voith | Flender-Graffenstaden | Nuttal |

| Black Clawson | Foote Jones | Philadelphia Gear* |

| Brad Foote | General Electric | Philadelphia Mixers |

| David Brown | Hamilton Gear* | Renk |

| John Brown | Hansen | Siemens |

| Chemineer | Hitachi | Standard Machine* |

| Cleveland | Horsburgh & Scott | Sumitomo |

| Delaval Steam Turbine | Lightnin | Thyssen |

| D.O. James | Link-Belt | Wes-Tech* |

| Elliott | Lufkin | Western Gear* |

| Falk | Maag | Westinghouse |

*Philadelphia Gear, WesTech, Western Gear, Delaval Steam Turbine, Standard Machine, and Hamilton Gear are all registered trademarks of The Timken Company or its affiliates.

ReverseEngineeringCapabilities

Besides having the ability to repair other brands, our service center can manufacture new Standard Machine gearboxes as drop-in replacements for virtually any brand industrial gearbox for a variety of applications. This is made possible by our extensive machining and fabrication capabilities, a trademark of our business. Our 100,000 square foot facility houses a heat-treating center capable of producing carburized gears up to 60” and tooth induction hardened gears up to 90”. Our shop is outfitted with boring mills that can handle up to 110,000 lbs. on our rotary table, and we have dedicated 10,000 square feet of space to support our CWB level 2 certified welding capabilities. So, whether you’re looking for a gearbox to meet or exceed the original design, our new drop-in gear boxes will fit the original footprint and be optimized for your application.

Standard Machine is capable of reverse engineering any industrial gear drive or component to exact OEM specifications by using state-of-the-art inspection and measuring techniques so we can offer a complete solution for virtually any gearbox repair.

GearboxRepairProcess: Inspection,DisassemblyandReassembly

Our inspection process includes a comprehensive visual inspection and can consist of non-destructive testing such as magnetic particle inspection, dye penetrant tests, and ultra-sonic testing on various components to look for surface and sub-surface cracking. A detailed report (including photography) that clearly outlines our findings and summarizes our gearbox repair scope is then submitted to the customer.

Once the decision to overhaul the gear drive is made, our shop technicians fully disassemble, as well as clean the unit and schedule the manufacture of replacement parts. If an opportunity exists to upgrade components or our the customer agrees that uprating the gear drive would benefit them in the long-term, our engineers make the necessary changes and incorporate them into gearbox repair and manufacturing process.

When all new and reworked components are complete, the gearbox is reassembled and spin-tested on our 600HP test stand. The testing involves measuring temperature, sound and vibration levels, tooth contact and backlash, and bearing end play. The gearbox is epoxy painted, preserved for storage, and documentation is sent back to the customer with the unit.

GearboxRepairScopeofWork

Standard Machine’s gear drive repair scope includes comprehensive technical services that cover all of the following:

- Condition Monitoring

- Diagnostics

- Drive exchange program

- Engineered upgrades

- On-site inspection

- Predictive maintenance

- Experience with the complete drivetrain

- All bearing types

- Straight bevel gears

- Spiral bevel gears

- Couplings

- Herringbone gears

- Hydroviscous clutches and brakes

- Single or double helical gears

- Planetary/epicyclic gears

- Worm gears

GearboxUpgradeOpportunities

During the process of any industrial gearbox repair, Standard Machine’s engineers look for opportunities to improve obsolete designs and components that can help extend the lifecycle of our customer’s equipment and save them money in the long-term. Whether it’s heat-treating techniques adding diagnostic instrumentation or upgrading couplings, our engineers can help evaluate your gearbox and offer you custom solutions.

Industrial Gearbox Repair

Gearing

Automatic Gearbox Repairs Near Me

- Grinding to achive better tooth geometry

- In-house heat-treating to increase hardness

Bearings

- Analysis of speed and load conditions ensure proper bearing selection

- Closer tolerance rolling element bearings increase life

- Fluid film (sleeve-type) bearings evaluated to match current operating characteristics

Lubrication

- Addition of oil coolers

- Replace or augment splash lubrication with the addition of external lube system

- Shift to duplex filtration so the unit can be serviced while operating

- Upgrade lip seals to face seals

Driveshaft Repairs Near Me

GearboxRepair:HamiltonGearReducers

Automatic Gearbox Repairs Near Me

As a designer and manufacturer of our own Hamilton Gear drive reducers and specializing in custom application gearbox systems, it is only natural that our gearbox repair capabilities would include gear reducer rebuilds. Our Certified Gear Reducer Rebuild Program works with our customers to meet their requirements by offering complete gear drive repair in our rebuild program or a quick bearing change out to get them back in service. Our facility has been certified by Timken and our own stringent program requirements that meet the needs of some of the largest resource companies in North America.

We are capable of reverse engineering gear reducers and their associated gear components to help support our customer’s needs, as well as offering a secondary source for pricing instead of going back to the OEM for parts that may be too expensive or have extended lead times. Our gear repair rebuild program is supported by a 110,000 square foot facility and gear shop, four horizontal boring mills, and a dedicated group of journeyman industrial mechanics trained in AGMA failure modes and certified bearing assembly techniques.

Vw Gearbox Repairs Near Me

We also offer an exchange program for gear drives that are critical to your process. So, if you need a gearbox from a centrifuge, conveyor, exciter, flotation, compaction, bucket, elevator, take-up winch, top drive, or winch drive, we are prepared to offer you a gearbox repair solution that meets your needs.